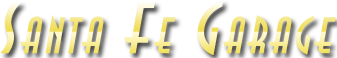

What is camber? (in degrees): the angle between a line drawn through the top and bottom of the tire (green line) and true vertical as viewed from the front. This is static camber. The tire leaning in, toward the center of the car, is negative camber; the tire leaning out is positive camber. Why do most performance cars specify negative camber? What is the optimal amount of camber?

Camber is just one of several attributes for a suspended wheel. We also have caster, toe and Ackerman. Ackerman is only mentioned because it affects toe when the wheel is turned. It is not significant in road racing and only slightly so with autocrossing. So why pick out camber; they are all interrelated, that is, adjusting one affects the others. Describing the sequence of adjustments and their impact is somewhat like trying to describe the beginning and end of a circle, they are all connected. This article focuses on camber because it has the highest significance on a performance road car relative to the others, then caster; mostly because of its effect on dynamic camber, and finally toe.

Why have negative camber? One of the goals of a car’s suspension system is to maximize lateral grip. This can be defined as the coefficient of friction which is the lateral load (Fy, the force the tire can withstand without sliding sideways) divided by the vertical load (Fz, the weight on the tire). It has been demonstrated in testing that for a given vertical load, the lateral load the tire can withstand, without losing grip, can be increased by tilting the top of the outside tire (right tire for left hand turn) towards the center of the car. That is, by adding negative camber.

The effect reaches a maximum at about 5 degrees with radial tires. This is a general statement; there are many other variables such as tire width and type of tire construction. Also, the test was measuring the effect of dynamic camber, i.e., the tire loaded and executing a turn of about 6 to 7 degrees. [reference: Milliken & Milliken, Race Car Vehicle Dynamics]. So, we want some dynamic, negative camber in a performance road car.

Does negative camber have undesirable effects?

Yes. For example, what would be the best camber for maximum braking and acceleration? 0 degrees camber gives you the best contact patch and therefore the best performance with heavy braking. Static negative camber will usually cause the inside of the tire to wear more than the outside. On a street car this is a cost issue. On a race car, you consider this because the tire has to make it to the end of the race or to the next pit stop, or last long enough to stay in your tire budget.

The impact of static negative camber will vary based on driving style and road conditions. You can extend the tire life for tires that wear unevenly by “flipping” the tires, but the labor cost may exceed the savings in tire cost. Flipping the tires will also decrease performance until the tire wears flat relative to the road because you have reduced the contact patch.

Camber thrust, the tendency of a tire to move in the direction of the camber, can make the car darty on uneven road surfaces. This is why cross camber, described later, is an important measurement on a street car.

Why do some cars call for more static negative camber than others?

The suspension geometry dictates how much static negative camber is needed in order to have the appropriate amount of dynamic camber. Manufactures give static alignment specifications that hopefully result in the appropriate dynamic settings. This is done because taking and setting dynamic measurements is very time consuming and expensive.

A well designed dual, control arm front suspension, e.g., late model Corvette, does a much better job of maintaining proper dynamic camber than a McPherson style front suspension. The Corvette will call for about 1 degrees of static negative camber; a Mustang with McPherson style will call for 2 to 3 degrees. They are both targeting the appropriate dynamic camber. Why the difference? Because of the difference in SAI (Steering Axis Inclination), this is much larger on a McPherson style.

SAI , viewed from the front of the car, is defined by the angle between a line going through the lower ball joint and the upper ball joint, or on a McPherson style the lower ball joint and the upper mounting point of the strut, and a vertical line. SAI causes camber to be reduced as the wheel is turned. Therefore, less is better. McPherson style, because of design restrictions, have large SAI, 10 to 12 degrees is normal. A dual control arm design has significantly less SAI.

At his point you might say, I don’t want less negative camber as I turn, I want more negative camber as I turn. That is, you do not want negative camber to go from negative 3 degrees to negative 2 degrees as you turn. You want it to increase. It does, because of the affect of caster (positive) and the movement of the control arm. For McPherson strut cars the lower control arm in its static position, goes down slightly as it goes toward the tire. As the arm swings in its arc during body roll in a corner, the arm gets longer, increasing negative camber. On a dual control arm design, negative camber increases are caused by the same influence of the lower control arm plus the upper control arm gets shorter relative to the lower as it swings through its arc.

What is cross camber?

Cross camber is the difference between the two camber measurements on an axle. For example, if the LF (Left Front) camber is 1.2 degrees negative and the RF (Right Front) is 0.5 degrees negative, the cross camber is 0.7 degrees. Why is this an important measurement, especially on a street car? With camber comes the phenomenon of camber thrust. Even if a tire is pointed straight ahead. It pushes the car laterally in the direction the tire is leaning. This is why, some cars (driven on the right hand side of the road), call for a little more negative camber for the RF than the LF. 1.0 degree camber causes camber thrust which is equivalent to turning the tire 0.1 degrees.

What about suspension modifications like lowering a car?

What about suspension modifications like lowering a car?

In many cases, we can get the car to the static alignment specifications even after it has been lowered, but this does not mean the car will handle as well as before. Why, because the dynamic measurements – car loaded in a corner, body rolling 1 or more inches – will have the control arm in a different location than the non lowered car which will affect the dynamic camber. For example, say a McPherson suspension set at 2.5 negative static camber at stock ride height has a dynamic camber in a 7 degree turn of 3.5 degrees negative. The car is lowered so the front lower control arm now goes up from the cross member (frame mounting point) to the lower ball joint by the wheel; it went down slightly before lowering. The static camber is re adjusted to the 2.5 negative setting, but the dynamic camber at the same 7 degree turn is now 2.5 degrees, not the more desirable 3.5 degrees. There is less impact on dual control arm cars, but the same phenomenon occurs.

So, what is the best setting for camber?

On a performance street car, start with the factory specifications. Accept that the tires on some cars will wear unevenly. Two examples are BMWs and McPherson strut cars. The former because of aggressive alignment settings and the latter because of limitations of the suspension design.

For autocross, track-day, and road-race cars start with asking what the successful guys running your car are doing. Unless you’re a podium finisher, they will probably share. If starting from factory settings, for an autocross or track day car, you can be a little more aggressive with camber, plus 1 degree. For a production road race car or purpose built autocross, plus 2 degrees. Again, this is for radial tires. Bias ply tires have different behavior. Then start taking tire temperatures.

Use a Probe type temperature gauge, not an infrared. Infrared only measures the surface temperature of the tire. Measure the tire temperature in three places across the tire, 1 inch form each outer edge and in the middle. Don’t take a cool off lap. Don’t get out of the car. Come in and as you stop, turn the wheels to give the crew easy access to the front tires. Have them take the temperatures and write them on the car with dry erase markers, left to right, inner, middle, outer. Also, measure the tire pressures.

Note the difference between a tire pressure issue and an alignment issue. For example, if the temperatures for a given tire, inner to outer, are 165, 185, 170, your tire pressure is too high. Drop it a few pounds and try again.

Excluding tire pressure issue, if your temperatures have about 10 degree or less variance, you are good to go. With a greater than 20 degree variance, try some changes, but watch your lap times – the end goal.

When making changes, change one thing at a time. Re adjust items that are affected by the change. For example, if you change camber, reset the toe. Now you might ask why re-set the toe if toe is not significant. Toe is not significant for cornering performance after initial turn-in. Even at turn-in, toe performance is debatable. It has been our experience that shock settings have a larger impact on turn-in behavior than toe settings. But, it can scrub off speed on the straights which is the most significant area of the track for reducing lap times.